(2006) do a design for the integrated system presented in Figure 8.6. Starting from the work of Henriksen et al. Develop a design of a duct burner that produces steam at two pressures and try to maximize its exergy efficiency.

Net workdone in brayton cycle generator#

2.Ĭompare the exergy efficiency of a steam generator to that of an ammonia–water vapor generator starting from the diagrams in Figure 8.4. One can assess this comparatively, that is by comparing efficiencies (energy, exergy) of the single-stage system with a two-stage or three-stage expansion system. Assess the benefit of turbine staging with interstage reheating to 800 ☌. Indirect heat removal is required from the fuel cell stack by compressed air, initially at low temperature to enable significant conversion of the fuel flow in the cells.ĭesign a transcritical Rankine cycle with carbon dioxide having condensation at 30 ☌ and a temperature at turbine inlet of 800 ☌.

Precise balancing of the anode and the cathode operating pressures are required to prevent rupture of the fuel cell electrolyte and High-pressure operation of the fuel cell system is required

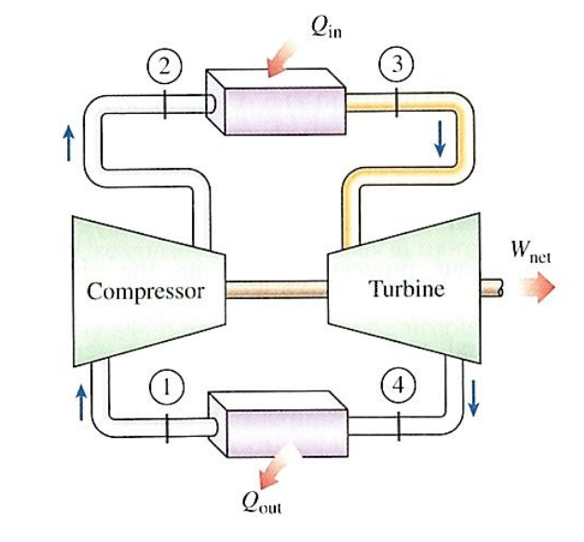

The system is highly efficient in heat recovery. Integrated plant and equipment are available for adaptation to fuel cell heat recovery and The cycle arrangement is more complicated compared to the regenerative Brayton cycle arrangement. Ĭooling and feed water are required and.The Rankine cycle inherently has a lower efficiency as compared to the regenerative Brayton and combined Brayton–Rankine cycles Steam is available for hybrid applications requiring heat. There is no need for a compressor fans for maintaining air and exhaust product gas flow will be sufficient and Heat is recovered in a boiler while a high temperature gas-to-gas heat exchanger is required in the regenerative Brayton cycle The fuel cell is operated under ambient pressure condition The efficiency and work output of the cycle is related to the compressor and the turbine efficiencies, pressure losses, and temperature differentials. Ī large gas-to-gas heat exchanger is needed for the case of high temperature heat recuperation and.The operating conditions of the compressor and the turbine equipment are limited to the fuel cell temperature and cycle operating pressure Industrial compressor and turbine equipment can be adapted for this application. The concept is more adaptable to small-scale power generation systems and

Net workdone in brayton cycle full#

0 kommentar(er)

0 kommentar(er)